HONYLITE - Honeycomb Core & Panel

news from HONYLITE, info, thoughts, opinions....!!! The structural honeycomb core provides strength and consistent rigidity at a very low density; when bonded to similarly lightweight facings. Every honeycomb cell wall acts like the web of an I-Beam, forming an extremely strong and rigid lightweight composite panel. The images used herein are again done to describe an idea than to advertise a certain product. So, read on.... and do leave your comments too.

Tuesday, 17 June 2014

Friday, 6 June 2014

Thursday, 3 April 2014

Friday, 28 February 2014

Sunday, 23 February 2014

Monday, 3 February 2014

Sunday, 2 February 2014

Aluminum Honeycomb Core is an Ideal Energy Absorber

Aluminum honeycomb core is an ideal energy absorber and provides a distinctive advantage over other energy absorbing materials in the market. It has a high crush strength to weight ratio, a linear force curve with a constant load, and it absorbs energy over a long stroke.

Saturday, 8 September 2012

What are Composites?

Composites offer a range of properties such as tremendous durability and high specific strength, which are impossible to match with traditional materials. Moreover, they allow the design of complex geometric forms and the engineering of bespoke materials precisely tailored to meet the demands of the particular application.

THE ADVANTAGES OF COMPOSITES

These beneficial characteristics have enabled the rapid incorporation of composites within a wide range of industries from deep sea, polar and space exploration to household appliances and building facades.

EXAMPLES OF COMPOSITE APPLICATIONS

Boats are a good example of the successful application of composites and also happen to be one of the earliest mass applications of the technology. Boats can be made out of a variety of materials – wood, aluminium, steel, and even concrete, yet most pleasure boats today are built from fibreglass composites. The reason is that composites can be easily moulded into complex shapes, which improve boat design, and the structure requires minimal maintenance despite being exposed to an extremely harsh marine environment.

This inherent durability of composites is attractive to many industries, and not least of all the construction industry. Many structures have now been in service for more than 50 years.

EXAMPLES OF COMPOSITE APPLICATIONS

Boats are a good example of the successful application of composites and also happen to be one of the earliest mass applications of the technology. Boats can be made out of a variety of materials – wood, aluminium, steel, and even concrete, yet most pleasure boats today are built from fibreglass composites. The reason is that composites can be easily moulded into complex shapes, which improve boat design, and the structure requires minimal maintenance despite being exposed to an extremely harsh marine environment.

This inherent durability of composites is attractive to many industries, and not least of all the construction industry. Many structures have now been in service for more than 50 years.

PREPREG PRODUCTION LINES, TURN KEY FROM UNIVERSAL METALTEK

Universal Metaltek offers a “turn-key” cost effective solutions to prepreg production, designed and engineered by tipton-Goss, which can be quickly and easily be utilized by start-

up “prepregers” and composite parts manufacturers.

Tipton-Goss offers the smoothest and most cost-effective entry into prepreg production through a combination of novel products and expertise unique in the industry:

• Novel and highly cost-effective prepreg fabric machine TG-50-F, TG-60 and Unidirectional Tape and Resin Filmers (TG-24-T – 1 meter)

• Complete engineering responsibility; (formulation, mixing, prepreg-processing)

• Mix equipment that is designed specifically to work in concert with Tipton-Goss machinery

• Over 20 years of experience in prepreg production

• Novel Resin formulating technologies scanning a broad range of technologies

• Working Showroom and training facility with all aspect of prepreg production

• Customers have the opportunity to train on actual prepreg production prior to machine delivery

• By passing unneeded reps., sourcing of all the materials necessary to be successful (All materials are

produced by top-level, certified, global suppliers)

The highlights of our offer are:

1) A full-service approach, from formulation through methods, sourcing and training (Our customers get much more than just equipment, they get a running production facility).

2) Compact and simple machinery, designed specifically for all types of users, with the option of upgrades necessary to satisfy the highest expectations from Space to Sporting Goods.

A prepreg production line grants users a number of key advantages:

- Development of exclusive products with very high performances to meet or exceed expectations

- A stable source of raw materials sourced to guaranty continued production

- Cost reduction by eliminating of the need to invest in large inventory and frozen storage

- Eliminate the dependence to work with difficult suppliers many of which are tight on capacity

TG-50-F 50”FABRIC MACHINE

The TG-50-F coater consists of a unitized structural steel frame, turret unwind, driven pull roll, two sided reverse roll coaters with hot melt feed plates, dual position auxiliary unwind and single position winder.

• Designed for limited maintenance

• Highest quality and domestically-sourced components

• Ergonomically designed

• Easy operator access and control features

• Bulletproof construction, extra thick side frames, oversized bearings

TG-1.1meter 43” UNI-TAPE MACHINE

The TG 1meter is Tipton-Goss’s novel 1meter unidirectional tape machine and filmer. It utilizes in-line film-coating for the resin-impregnation of unidirectional tape, up to 1 meter in width.

• Ideal for Developmental or Light-to-Moderate Production

• Designed for Limited Maintenance

• Highest-Quality, Domestically-Sourced Components

• “Bulletproof” Construction; Extra-Thick Side Frames and Oversized Bearings

• Ergonomically-Designed for Easy Operator Access and Control

Tipton-Goss offers the smoothest and most cost-effective entry into prepreg production through a combination of novel products and expertise unique in the industry:

• Novel and highly cost-effective prepreg fabric machine TG-50-F, TG-60 and Unidirectional Tape and Resin Filmers (TG-24-T – 1 meter)

• Complete engineering responsibility; (formulation, mixing, prepreg-processing)

• Mix equipment that is designed specifically to work in concert with Tipton-Goss machinery

• Over 20 years of experience in prepreg production

• Novel Resin formulating technologies scanning a broad range of technologies

• Working Showroom and training facility with all aspect of prepreg production

• Customers have the opportunity to train on actual prepreg production prior to machine delivery

• By passing unneeded reps., sourcing of all the materials necessary to be successful (All materials are

produced by top-level, certified, global suppliers)

The highlights of our offer are:

1) A full-service approach, from formulation through methods, sourcing and training (Our customers get much more than just equipment, they get a running production facility).

2) Compact and simple machinery, designed specifically for all types of users, with the option of upgrades necessary to satisfy the highest expectations from Space to Sporting Goods.

A prepreg production line grants users a number of key advantages:

- Development of exclusive products with very high performances to meet or exceed expectations

- A stable source of raw materials sourced to guaranty continued production

- Cost reduction by eliminating of the need to invest in large inventory and frozen storage

- Eliminate the dependence to work with difficult suppliers many of which are tight on capacity

TG-50-F 50”FABRIC MACHINE

The TG-50-F coater consists of a unitized structural steel frame, turret unwind, driven pull roll, two sided reverse roll coaters with hot melt feed plates, dual position auxiliary unwind and single position winder.

• Designed for limited maintenance

• Highest quality and domestically-sourced components

• Ergonomically designed

• Easy operator access and control features

• Bulletproof construction, extra thick side frames, oversized bearings

TG-1.1meter 43” UNI-TAPE MACHINE

The TG 1meter is Tipton-Goss’s novel 1meter unidirectional tape machine and filmer. It utilizes in-line film-coating for the resin-impregnation of unidirectional tape, up to 1 meter in width.

• Ideal for Developmental or Light-to-Moderate Production

• Designed for Limited Maintenance

• Highest-Quality, Domestically-Sourced Components

• “Bulletproof” Construction; Extra-Thick Side Frames and Oversized Bearings

• Ergonomically-Designed for Easy Operator Access and Control

Monday, 27 August 2012

PREPREG - PRODUCTION LINE

EXCLUSIVE DISTRIBUTOR

UNIVERSAL METALTEK distributes Component in INDIA: Production Line TIPTON GOSS for pre-impregnated "turnkey" more convenient and complete.

Tipton Goss supplies state of the art know-how and turn-key plants for the production of hot melt prepregs.

Our strengths:

1) full-service approach, from formulation through sampling, methods, sourcing, design, equipment and training

2) the compact scale of our machinery, unique on the market, designed specifically for big users of preimpregnated fabric and uni-directional tapes

3) TG know-how ranges from aerospace to industrial applications.

UNIVERSAL METALTEK distributes Component in INDIA: Production Line TIPTON GOSS for pre-impregnated "turnkey" more convenient and complete.

Tipton Goss supplies state of the art know-how and turn-key plants for the production of hot melt prepregs.

Our strengths:

1) full-service approach, from formulation through sampling, methods, sourcing, design, equipment and training

2) the compact scale of our machinery, unique on the market, designed specifically for big users of preimpregnated fabric and uni-directional tapes

3) TG know-how ranges from aerospace to industrial applications.

INDIA COMPOSITE SHOW

Participating in the INDIA COMPOSITE SHOW New Delhi 2012, starting from 1st November 2012.

For more info. log onto http://www.universalmetaltek.com/

For more info. log onto http://www.universalmetaltek.com/

Sunday, 20 February 2011

HONYLITE Aluminum Honeycomb Panel

The surface of the HONYLITETM aluminum honeycomb panels are made of aluminum alloy plates roller coated with PVDF while in the middle are the aluminum honeycombs which meets the international aeronautical standards. This product is specially made with the cold-glue and hot-press technology.

The structural honeycomb core provides strength and consistent rigidity at a very low density; when bonded to similarly lightweight facings. Every honeycomb cell wall acts like the web of an I-Beam, forming an extremely strong and rigid lightweight composite panel.

HONYLITETM honeycomb panel is an aluminum sandwich-type panel with high rigidity and extremely low weight. It is the ideal material for a most of applications in architecture, transport, display or industrial production.

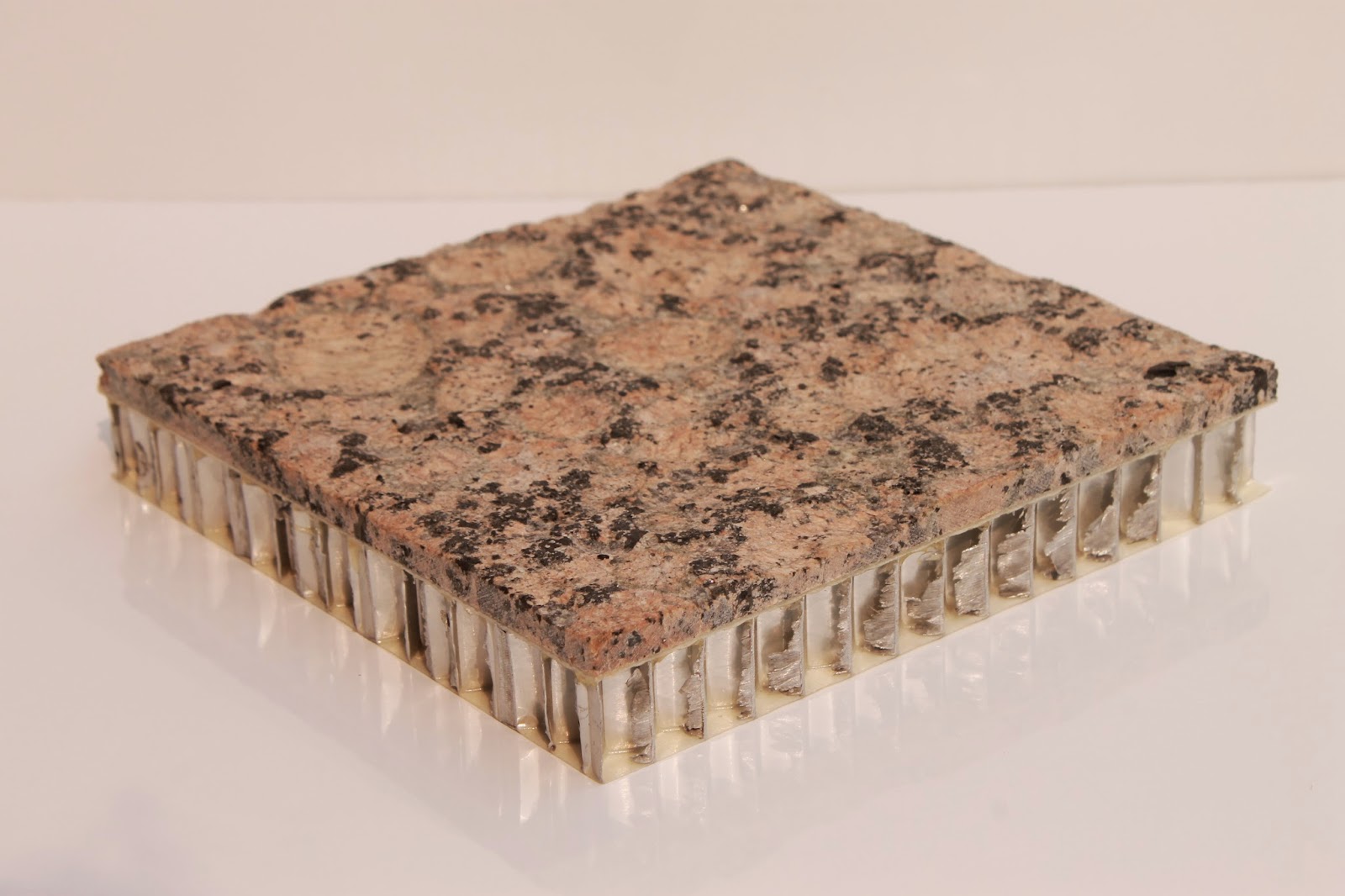

The development history of the honeycomb stone panel

Super thin honeycomb stone panel was first invented in Ireland. The first piece in the world was made in 1973. In 1983, an American company succeeded in producing the same product. A German company produced the super light stone wave composite which is quite similar to the super thin honeycomb panel in 1989 and then in 1990, two Italian companies have also started the production. In 2000 Chinese and in 2001 Russians began their production. So the production of super thin honeycomb stone panels has passed a history of 30 years and now is a fully mature product. The application in many engineering projects has proved many superiorities of this product.

HONEYCOMB PANELS

Early in the forth century, the Greek mathematician Pepose declared that the smart shape of honeycomb is the representative of the most effective labor of the nature. At that time, he guessed "The hexagon honeycomb which mankind can see is made with the least beeswax." This guess is known as "honeycomb guess.”

Darwin, the famous biologist even insisted "the man must be muddle-headed if he does not pay double tribute when he sees the honeycomb."

Darwin, the famous biologist even insisted "the man must be muddle-headed if he does not pay double tribute when he sees the honeycomb."

Subscribe to:

Comments (Atom)